Each machine has an expected life of 5 years. 10 of compounds.

Small Scale And Large Scale Capsule Filling Machine

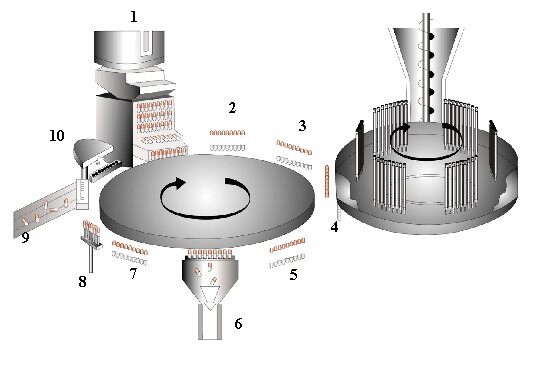

Automatic Capsule Filling Machine Njp Series Working Principle Ipharmachine

Tamping Pin Capsule Filling Machine Vs Dosator Type Capsule Filling Machine The Ultimate Comparison Knowledge Trustar Pharma Pack Equipment Co Ltd

What is Acceptable Quality Level AQL.

Capsule filling machine working principle. Two machines are available E and F. Fill then top off when filling the gas tank of your car. More Americans are working into old age.

Net Profits before tax and after depreciation during the expected life of the machines are given below. The machine for testing may be portable or a stationary type. The pressure gauges cover scale ranges from 0.

It is a high-tech filling equipment controlled by microcomputer PLC programmable. Whenever youre shopping for any type of tablet coating machine it is important to know the working principle design structure air capacity coating composition and efficiency. The cost of each machine is Rs 60000.

In this session people are able to think more freely and they suggest as many spontaneous new ideas as possible. In the time course from its first day founded to today withperiodically manufacturing facility and machine investments while keeping up withnowadays manufacturing technology and speed with our products of which we evermade no compromise in quality we live the legitimate pride of reaching to our customersBy this time in addition to our countless references we had in manufacturingsector. Even though there are many types of hammer mills the working principle is still the same.

Or use a stencil--this is an application of Principle 3 Local Quality and Principle 9 Preliminary anti-action. You may also check out our blog on. Alcohol bottle filling machine.

Working principles of tablet coating machines. Acceptable Quality Level AQL is a percent defective that is the base line requirement for the quality of the product. I know this process may be overwhelming at times.

Filling machinery to meet the specifications of your commercial wine filling and liquor filling applications. Mettler Toledo balance tablet dept. The working principles of tablet coating machines are relatively simple.

This position is primarily due to its super simple and automated descaling process. The Working Principle of Hammer Mills Step-by-step Guide A hammer mill is an essential machine in the pharmaceutical and food processing industries. Senieer FBM Series fluid bed processor working principle offers the possibility to dry granulate or coat particles in a single machine.

Is considering the purchase of a machine. 85000 psi and indication accuracies of up to 01. There are three systems really.

The Magnificas steam wand breaks down into multiple. Fluid bed dryer animation fluid bed dryer operation. This principle is proposed to solve the following contradictions.

Overall we can call them the basic or common laboratory apparatus we use in a school physics chemistry biology and composite lab and it varies more or less depending on the type of laboratory a person is working in. For instance the main tower consists of. Sejong SF 40 auto capsule filling machine parts.

Tablet coating machines work by applying coating ingredients in the form of a solution to a group of tablets in a bed that may move horizontally or vertically. The DeLonghi Magnifica is the only non-capsule machine to grace the top tier of our ease of cleaning testing. For the optimal solution for the widest range of applications there is a choice of measuring systems in Bourdon tube diaphragm element and capsule element technologies.

Sejong SF 40 auto capsule filling machine parts ID No. You can use it to crush pulverize shred grind and reduce material to suitable sizes. Mk 1 Mod 0123.

NASA has completed assembly of the Artemis I rocket which will be used to launch the Orion crew capsule on an uncrewed mission around the moon in 2022. 05 mbar to 0. In this review we highlight the use of AI in diverse sectors of the pharmaceutical industry including drug discovery and development drug repurposing improving pharmaceutical productivity and clinical trials among others.

The Mod 2 featured a simplified overall design while the Mod 3 replaced the single-piece steel body with a two-piece plastic shell. Dental composite resins better referred to as resin-based composites or simply filled resins are dental cements made of synthetic resinsSynthetic resins evolved as restorative materials since they were insoluble of good tooth-like appearance insensitive to dehydration easy to manipulate and reasonably inexpensive. Fluid Bed Processor innovative technology allows fluid bed processor top spray systems to be changed to fluid bed processor bottom spray systems in just a few minutes.

While testing is being performed on this machine the load in the pound is visible on the gauge. 02 H 2 O to 0. The pressure gauges cover scale ranges from 0.

The sugar Murandu uses is the plain granulated type you might use to sweeten your tea. By doing so you will obviously optimize all operations in your tablet coating process. Type 1 diabetes machine is characterized as.

Disadvantages Capsule retention seen in 1 usually at site of pathologic obstruction Tumors Strictures Ulcers Advantages and Disadvantages of Encapsulation in Java The word Encapsulation means that closing something like we put the main power of the tablet inside the capsule. In the same in vitro trials he found that there was no difference between using cane or beet sugar. For a good understanding of the fluid bed dyers working principle you must know its parts.

Main tasks of machine structures are the assurance of the geometric configuration of the machine elements even under static dynamic and thermal loads as well as the absorption and guiding of forces and torques. The Mod 1 probably featured an improved type fuze moving away from the simple wick lighter design. You can then process the Softgel capsules further by drying polishing or printing.

Bottle Cleaner 4 Capsule 4 Case Packer 10. The sampling plan required to be prepared or design in such a way that there is high probability of accepting a. The working principle of soft gelatin capsule filling machine involves preparing gelatin fill material preparation and actual encapsulation process.

An illumination grenade with a magnesium filler ignited by a wick type fuze the Mk 1 Mod 0 was first produced during the Second World War. Step-1 Brain StormingWhat is Brain Storming Brainstorming is a situation where a group of people meet to generate new ideas and solutions to find a conclusion for a specific problem. A portable testing machine working on a hydraulic principle that is enough to pull and bend the specimen is shown in Figure.

Soft gel capsules can break down with heat and age. The frame structure of a machine tool is an essential functional component inside the machining system. The use of artificial intelligence AI has been increasing in various sectors of society particularly the pharmaceutical industry.

The term was popularized by. Such use reduces the human workload. Air handling unit AHU Main stainless steel tower.

For the optimal solution for the widest range of applications there is a choice of measuring systems in Bourdon tube diaphragm element and capsule element technologies. 6000 bar and indication accuracies of up to 01.

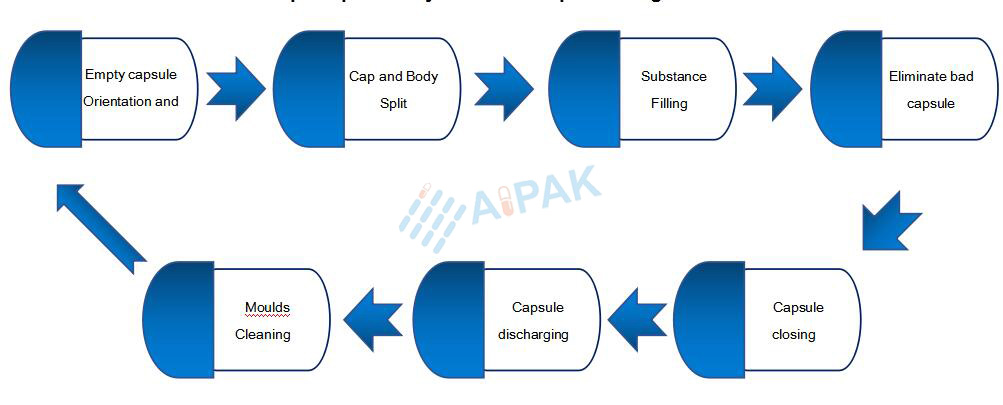

Capsule Filling Machine Aipak

Pam S Automatic Capsule Filling Machine Af 40 For Tamping Dosating Or Volumetric Filling

Study Of A Low Dose Capsule Filling Process By Dynamic And Static Tests For Advanced Process Understanding Sciencedirect

Njp 1200c Automatic Capsule Filling Machine Changzhou Wealth International Trading Co Ltd

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules Knowledge Trustar Pharma Pack Equipment Co Ltd

Automatic Capsule Filling Machine The Most Ultimate Importing Guide Capsule Filling Machine Your Best Online Resource About Capsule Fillers

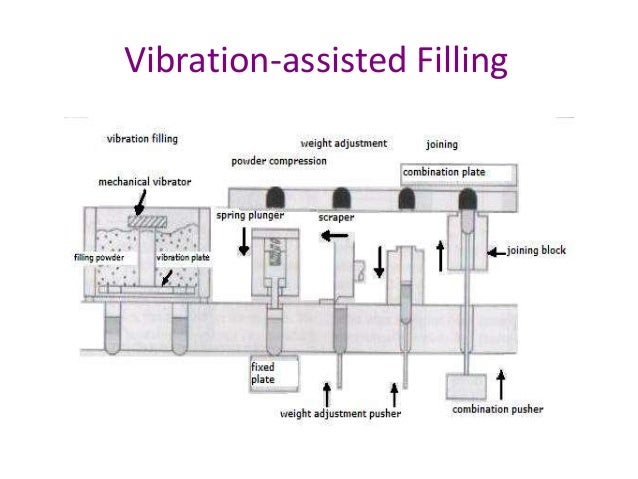

Figure 9 Capsule Filling Machines Working Principle Saintytec

Hard Shell Capsule Filling Machines Basicmedical Key